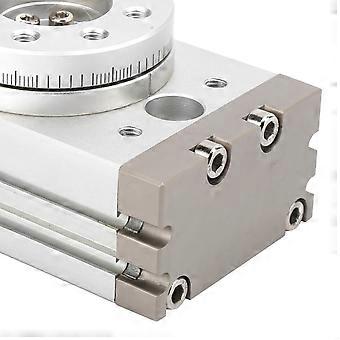

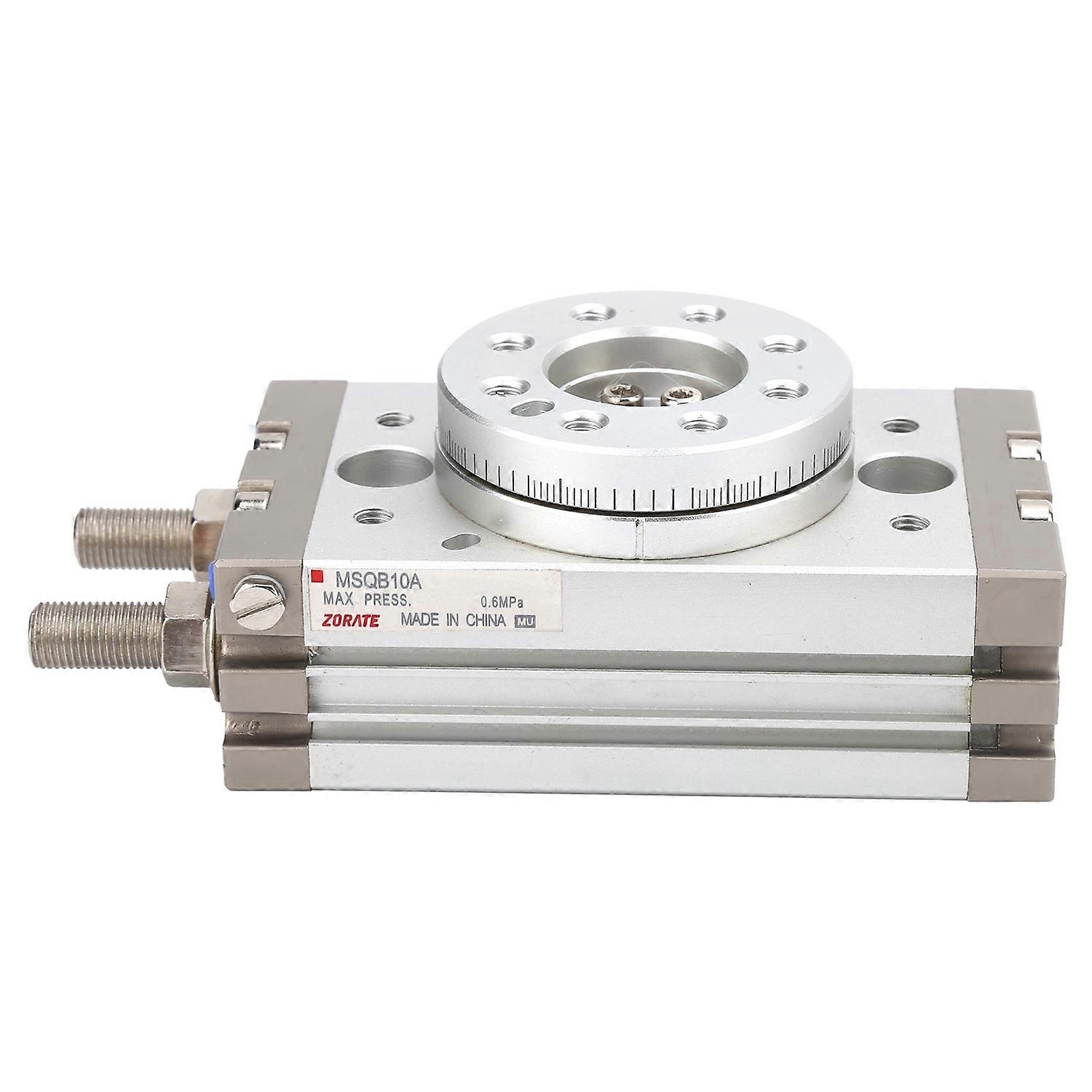

Pneumatic Air Cylinder Rack Type Rotary Swing 10mm Bore Alloy Steel Hardware MSQB10A

GRATIS Levering

Pneumatic Air Cylinder Rack Type Rotary Swing 10mm Bore Alloy Steel Hardware MSQB10A

- Brand: Unbranded

Pneumatic Air Cylinder Rack Type Rotary Swing 10mm Bore Alloy Steel Hardware MSQB10A

- Brand: Unbranded

Spar 175,00 DKK (25%)

Vejl. Pris

Spar 175,00 DKK (25%)

Vejl. Pris

Vi accepterer følgende betalingsmetoder

Beskrivelse

- Brand: Unbranded

- Kategori: Terapigynger

- Fruugo ID: 334922729-737741776

- EAN: 7695727774131

Produktsikkerhedsinformation

Se venligst produktsikkerhedsoplysningerne, der er specifikke for dette produkt, beskrevet nedenfor

Følgende oplysninger leveres af den uafhængige tredjepartsforhandler, der sælger dette produkt.

Produktsikkerhedsmærker

Levering og returnering

Sendt inden for 2 dage

-

STANDARD: GRATIS - Levering mellem kl man. 10 november 2025–fre. 14 november 2025 - GRATIS

Afsendes fra Kina.

Vi gør vores bedste for at sikre, at de produkter, du bestiller, leveres til dig fuldt ud og i henhold til dine specifikationer. Skulle du dog modtage en ufuldstændig ordre eller andre ting end dem, du bestilte, eller der er en anden grund til, at du ikke er tilfreds med ordren, kan du returnere ordren eller produkter inkluderet i ordren og modtage en fuld refusion for varerne. Se fuld returpolitik

Detaljer om produktoverholdelse

Se venligst overensstemmelsesoplysningerne, der er specifikke for dette produkt, beskrevet nedenfor.

Følgende oplysninger leveres af den uafhængige tredjepartsforhandler, der sælger dette produkt.

Producent:

De følgende oplysninger angiver kontaktoplysningerne for producenten af det relevante produkt, der sælges på Fruugo.

- Shenzhen Loma Li Technology Co., Ltd.

- Shenzhen Loma Li Technology Co., Ltd.

- nanwan jiedao xialilang shequ pingji dadao 1 hao jiansheng dasha A1215

- Longgang

- Shenzhen

- CN

- 518115

- gnng1213@163.com

- 18664926702

- https://hengruigongju.1688.com/page/index.html?spm=0.0.wp_pc_common_header_companyName_undefined.0

Ansvarlig person i EU:

De følgende oplysninger angiver kontaktoplysningerne for den ansvarlige person i EU. Den ansvarlige person er den udpegede økonomiske aktør med hovedsæde i EU, der er ansvarlig for overensstemmelsesobligationerne i forbindelse med det relevante produkt, der sælges til den Europæiske Union.

- None

- Kequ Technology s.r.o.

- Pražákova 1008/69

- Štýřice

- Jihomoravský kraj

- Brno

- CZ

- 63900

- christopher25106@outlook.com

- 420608214795

- https://www.ozon.ru/seller/docool-583119/products/?miniapp=seller_583119