Beskrivelse

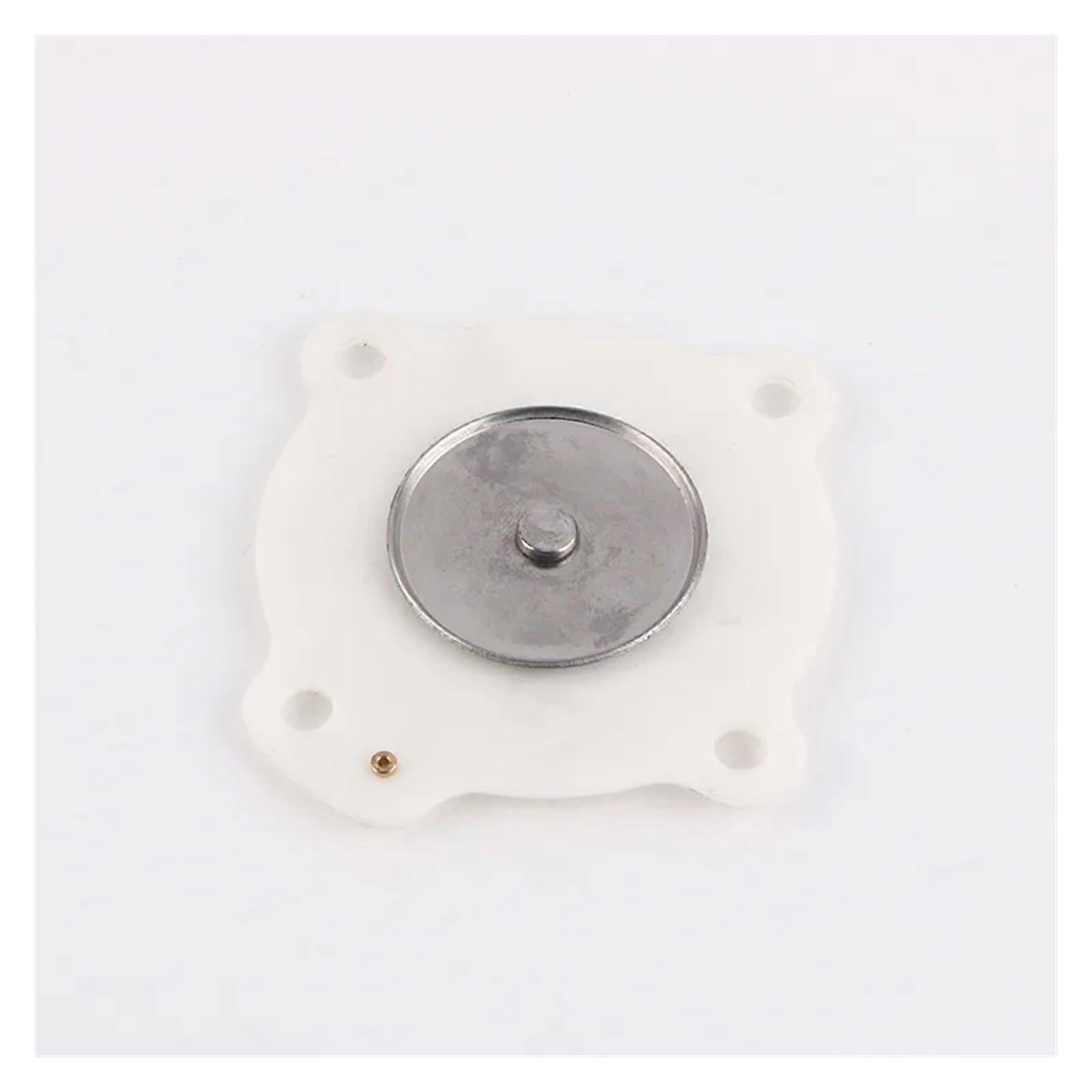

Electromagnetic Pulse Valve Diaphragm SCG353A044 A043 Dust Removal Valve Diaphragm

Control Valves

Overview

A control valve modulates flow in a piping system to maintain a setpoint for process variables such as flow, pressure, or temperature. It uses an actuator to move the valve mechanism (seat, plug, or disc) in response to a control signal. The result is precise, stable process control with reliable shut-off when the valve is fully closed.

Key benefits

- Precise modulation: ensures target flow or pressure is reached with minimal overshoot and short response time.

- Reliable shut-off: tight sealing reduces leakage when closed, supporting system integrity and safety.

- Broad media compatibility: suitable for water, oil, gas, steam, and many chemicals when paired with appropriate materials and seals.

- Durable construction: available in common industrial materials such as stainless steel, carbon steel, bronze, and ductile iron to fit demanding service conditions.

- Flexible actuation: supports electric, pneumatic, or hydraulic actuation, with compatibility to standard control systems and optional positioners or feedback devices for closed-loop control.

- Easy installation and maintenance: modular design, standard end connections, straightforward disassembly for service, and predictable maintenance intervals.

- Consistent performance: designed for stable control with reliable endurance under typical process fluctuations and cycle demands.

Attributes to consider

- Function: modulates fluid flow to maintain setpoints for process variables; provides controlled opening and closing for precise regulation.

- Compatibility: suitable for a range of media when equipped with appropriate seals and materials; compatible with common control signals and mounting styles.

- Size: offered in multiple pipe sizes to fit upstream and downstream components; selection aligned with valve Cv/Kv requirements and system needs.

- Material: construction options include stainless steel, carbon steel, bronze, and ductile iron; seats and seals available in EPDM, Viton, PTFE, and other materials to suit media and temperature requirements.

- Performance: emphasis on accurate positioning, tight shut-off, low hysteresis, and long valve life; designed to meet applicable industry standards for safety and reliability.

- Actuation options: electric actuators, pneumatic actuators, or hydraulic actuators; compatibility with local control systems; optional feedback and position indication.

- End connections: diverse connection types such as flange, tri-clamp, butt weld, or threaded ends to fit existing piping layouts.

- Standards and certification: designed to conform to relevant industry standards and operating conditions; available configurations may include certified options as required by the application.

Use scenarios

- Chemical processing dosing loop: deployed to regulate the flow of a reactant into a mixer, maintaining precise concentration and reaction conditions with rapid response to control signals.

- HVAC plant primary and secondary loops: used to modulate chilled or hot water flow in response to temperature setpoints, improving energy efficiency and comfort while protecting equipment from thermal shock.

- Water treatment and distribution: employed for precise dosing of coagulants or disinfectants and for balancing flow in distribution networks, supporting consistent water quality and system pressure.

Installation and operation tips

- Select the valve size and Cv/Kv to match the system’s flow demand and pressure characteristics for accurate control.

- Choose materials and seals that suit the media, temperature, and potential chemical exposure to minimize wear and leakage.

- Pair the valve with an appropriate actuator and, where needed, a positioner or feedback device to achieve reliable closed-loop control.

- Ensure proper alignment and mounting orientation to optimize actuator performance and longevity.

- Implement routine inspection and maintenance of seals, seats, and actuators according to service conditions and manufacturer recommendations.

This description provides a concise, practical overview of control valves with emphasis on function, compatibility, size, material, and performance. It includes 2-3 concrete use scenarios to illustrate practical application, and it maintains a professional, trustworthy tone suitable for informed purchasing decisions.

-

Fruugo ID:

375907553-813574527

Produktsikkerhedsinformation

Se venligst produktsikkerhedsoplysningerne, der er specifikke for dette produkt, beskrevet nedenfor

Følgende oplysninger leveres af den uafhængige tredjepartsforhandler, der sælger dette produkt.

Levering og returnering

Sendes inden for 24 timer

Afsendes fra Kina.

Vi gør vores bedste for at sikre, at de produkter, du bestiller, leveres til dig fuldt ud og i henhold til dine specifikationer. Skulle du dog modtage en ufuldstændig ordre eller andre ting end dem, du bestilte, eller der er en anden grund til, at du ikke er tilfreds med ordren, kan du returnere ordren eller produkter inkluderet i ordren og modtage en fuld refusion for varerne. Se fuld returpolitik